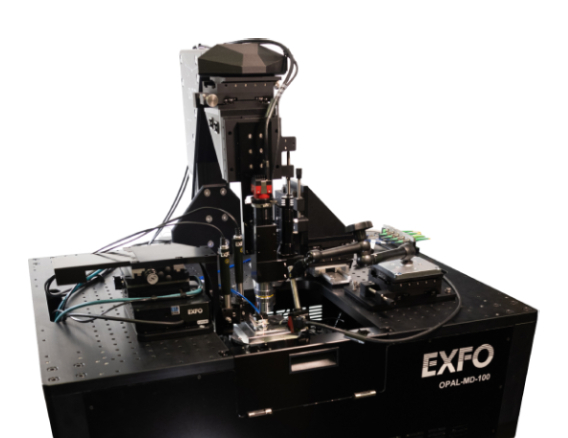

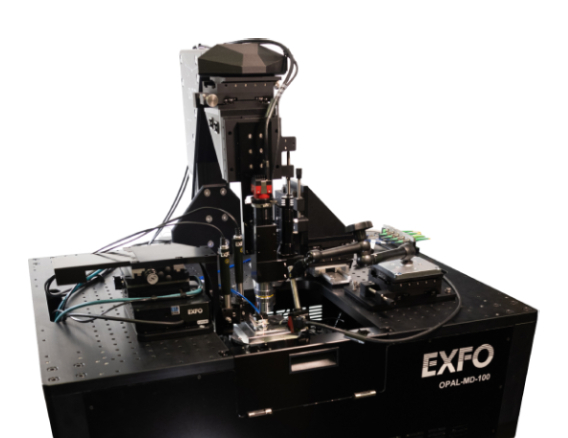

| A standard OPAL-MD test station includes | One OPAL-MD-100 chuck stage motion system, one TA chuck, a top and side vision system, PC with EXFO Pilot software license and accessories. |

| CHUCK STAGE MOTION SYSTEM – OPAL-MD-100 (Mechanical) | |

| X, Y axis – Travel range (mm) | 100 |

| X, Y axis – Resolution (μm) | 0.15 |

| X, Y axis – Accuracy, typical (μm) | 1 |

| X, Y axis – Bidirectional repeatability, typical (μm) | 1 |

| X, Y axis – Maximum process speed (mm/s) | 20 |

| X, Y axis – Motor type | Recirculating ball bearing, stepper motor |

| Z axis – Travel range (mm) | 4.8 |

| Z axis – Resolution (μm) | 0.06 |

| Z axis – Accuracy, typical (μm) | 0.6 |

| Z axis – Bidirectional repeatability, typical (μm) | 0.1 |

| Z axis – Maximum speed (mm/s) | 5 |

| Z axis – Motor type | Linear ball bearings, DC motor |

| Rz axis – Travel range | 15° |

| Rz axis – Resolution | 0.9 arcsec; 0.00025° |

| Rz axis – Accuracy, typical | 36 arcsec; 0.01° |

| Rz axis – Bidirectional repeatability, typical | 9 arcsec; 0.0025° |

| Rz axis – Maximum speed (degree/s) | 20 |

| Rz axis – Motor type | Crossed roller bearings, stepper motor |

| CHUCK | |

| Chuck – Option name | TA-F; TH1-G/F |

| Chuck – Work area (mm) | 100 × 100, square (TA-F and TH1-G/F) |

| Chuck – Range (TA-F) | Ambient |

| Chuck – Range (TH1-G/F) | Dew-point (>0 ºC) (32 °F) to 150 ºC (302 °F) |

| Chuck – Resolution (TA-F) | - |

| Chuck – Resolution (TH1-G/F) | 0.01 °C (32 °F) |

| Chuck – Stability (TA-F) | - |

| Chuck – Stability (TH1-G/F) | 0.05 °C (32 °F) |

| Chuck – Heating rate (TA-F) | - |

| Chuck – Heating rate (TH1-G/F) | 20 °C/min (68 °F/min) |

| Chuck – Cooling rate (TA-F) | - |

| Chuck – Cooling rate (TH1-G/F) | –10 °C/min (14 °F/min) |

| Chuck – Vacuum zones (TA-F and TH1-G/F) | 4 independent zones |

| Chuck – Electrical connection (TA-F) | Floating (F) |

| Chuck – Electrical connection (TH1-G/F) | Grounded (G)/Floating (F) |

| TOP VISION SYSTEM – Mechanical base holder | |

| Mounting | Compatible with metric and imperial optical breadboard, at 90° and 45° |

| X, Y, Z axis travel range (mm) | 48 |

| X, Y axis displacement/revolution (mm) | 1.41 |

| Z axis displacement/revolution (mm) | 0.3175 |

| TOP VISION SYSTEM – Vision system | |

| Magnification (X) | 10 |

| Numerical aperture | 0.28 |

| Depth of field (μm) | 3.6 |

| Horizontal field of view (mm) | 0.88 |

| Working distance (mm) | 34 |

| Resolution (MP) | 2.9 |

| Maximum frame rate (fps) | 144 |

| Sensor format (inch) | 2/3 |

| Sensor type | Color, global shutter, 12 bit |

| Wavelength | Visible |

| Illumination type | In-line through video microscope unit, LED illuminator |

| SIDE VISION SYSTEM – Mechanical base holder | |

| Mechanical positioning | 6D manual coarse adjustment with articulated arm, XY manual translation stage |

| Mounting | Compatible with metric and imperial optical breadboard, at 90° and 45° |

| X, Y axis travel range (mm) | 48 |

| X, Y axis displacement/revolution (mm) | 1.41 |

| SIDE VISION SYSTEM – Vision system | |

| Lens type | Telecentric |

| Magnificationa (X) | 3 |

| Numerical aperture | 0.093 |

| Field of view (mm) | 2.9 × 2.2 |

| Working distanceb (mm) | 65 |

| Wavelength range | Visible |

| Resolution (MP) | 2.9 |

| Maximum frame rate (fps) | 144 |

| Sensor format (inch) | 2/3 |

| Sensor type | Color, 12 bit, global shutter |

| Wavelength | Visible |

| OPTICAL HEADa – Options PRO-H / PRO-S / PRO-ECO | |

| Motorized axis (PRO-H / PRO-S / PRO-ECO) | X, Y, Z, Rx, Ry, Rz / X, Y, Z, Rx, Ry, Rzb / X, Y, Z, Rx, Ry, Rzc |

| Configuration (PRO-H / PRO-S / PRO-ECO) | Parallel hexapod, piezo / Serial stack, DC servo / Serial stack, screw |

| X axis travel (mm) (PRO-H / PRO-S / PRO-ECO) | 20 / 25 / 25 |

| Y axis travel (mm) (PRO-H / PRO-S / PRO-ECO) | 11 / 25 / 25 |

| Z axis travel (mm) (PRO-H / PRO-S / PRO-ECO) | 20 / 4.8 / 12.5 |

| X axis resolution (nm) (PRO-H / PRO-S / PRO-ECO) | 1 / 10 / 200 |

| Y axis resolution (nm) (PRO-H / PRO-S / PRO-ECO) | 1 / 10 / 200 |

| Z axis resolution (nm) (PRO-H / PRO-S / PRO-ECO) | 1 / 60 / 25 |

| X axis repeatability (nm) (PRO-H / PRO-S / PRO-ECO) | Unidirectional: 50 / Bidirectional: 70 / Bidirectional: 1250 |

| Y axis repeatability (nm) (PRO-H / PRO-S / PRO-ECO) | Unidirectional: 50 / Bidirectional: 70 / Bidirectional: 1250 |

| Z axis repeatability (nm) (PRO-H / PRO-S / PRO-ECO) | Unidirectional: 50 / Bidirectional: 250 / Bidirectional: 125 |

| Rx axis travel (º) (PRO-H / PRO-S / PRO-ECO) | 23 / 10 / 10 |

| Ry axis travel (º) (PRO-H / PRO-S / PRO-ECO) | 38 / 10 / 10 |

| Rz axis travel (º) (PRO-H / PRO-S / PRO-ECO) | 26 / 10 / 10 |

| Rx axis resolution (arcsec) (PRO-H / PRO-S / PRO-ECO) | 0.04 / 4 / 4 |

| Ry axis resolution (arcsec) (PRO-H / PRO-S / PRO-ECO) | 0.04 / 4 / 4 |

| Rz axis resolution (arcsec) (PRO-H / PRO-S / PRO-ECO) | 0.04 / 4 / 4 |

| Rx axis repeatability (arcsec) (PRO-H / PRO-S / PRO-ECO) | Unidirectional: 1.5 / 7 / 7 |

| Ry axis repeatability (arcsec) (PRO-H / PRO-S / PRO-ECO) | Unidirectional: 1.5 / 7 / 7 |

| Rz axis repeatability (arcsec) (PRO-H / PRO-S / PRO-ECO) | Unidirectional: 1.5 / 7 / 7 |

| Full virtual pivot point (PRO-H / PRO-S / PRO-ECO) | Yes / No / No |

| Orientations (PRO-H / PRO-S / PRO-ECO) | North/East/South/West / North/East/South/West / North/East/South/West |

| Includedc (PRO-H / PRO-S / PRO-ECO) | Fiber holder / Fiber holder / Fiber holder |

| ELECTRICAL HEAD – Options PRE-00 / PRE-MO | |

| Translation stages type (PRE-00 / PRE-MO) | Manual / Motorized X, Y, Z, manual probe angle |

| X, Y axis travel range (mm) (PRE-00 / PRE-MO) | 48 / 50 |

| Z axis travel range (mm) (PRE-00 / PRE-MO) | 48 / 25 |

| X, Y, Z axis resolution (nm) (PRE-00 / PRE-MO) | - / 100 |

| X, Y, Z axis repeatability (μm) (PRE-00 / PRE-MO) | - / 1, bidirectional, typical: 0.3 |

| X, Y, Z axis accuracy (μm) (PRE-00 / PRE-MO) | Typical: 2 / 5 |

| X, Y, Z axis speed (mm/s) (PRE-00 / PRE-MO) | - / 5 |

| X, Y, Z axis displacement/revolution (mm/rev) (PRE-00 / PRE-MO) | 0.3 / - |

| Tilt travel (PRE-00 / PRE-MO) | 10° / 10° |

| Rail system X travel (mm) (PRE-00 / PRE-MO) | 180 / 160 |

| Z coarse step travel (mm) (PRE-00 / PRE-MO) | PRE-00: Min: 6.35; Max: 56 / PRE-MO: Min: 12.5; Max: 100 |

| a. Other temperature ranges available upon request. b. Custom vacuum patterns and zones available upon request. c. Generic and custom vacuum adaptator plates available upon request. d. Other electrical connection options available upon request. a. Other magnifications options (0.5X, 1X, 2x, 4X, 6X, 8X) available upon request. b. Other working distances options (40 mm, 110 mm) available upon request. a. Other optical options and configurations are available upon request. b. Various configurations are available. X, Y, Z are always motorized and angles can be motorized, up to all 6 axes. Specifications here are for all motorized axes, travel may differ for manual version. c. Multiple options are available for surface and edge coupling configuration, multiple angles available. | |

| GENERAL SPECIFICATIONS – MAIN SYSTEM | |

| Size (H × W × D) | 1500 mm × 1095 mm × 945 mm (59 in × 43 1/8 in × 37 1/4 in) |

| Weight (kg)a | 350 kg (771.6 lb) |

| Operating environmentb | Use in a clean environment to avoid temperature variations, vibrations, humidity and dust |

| Base | Base frame with passive vibration isolation, canisters and feet |

| Maximum number of electrical or optical heads | Up to 4 |

| Optical breadboard | Grid of M6 threaded mounting holes, 25 mm hole spacing, black anodized for reduced reflections |

| Workstation computer | 4U rackmount industrial, Intel i7 CPU, 64 GB RAM DDR5, 1 TB SSD, Nvidia RTX 4060 GPU, 3 Ethernet ports (10 + 2.5 + 1 Gbit/s), multiple USB ports, additionnal PCIe slots, Windows 11 Pro, mouse and keyboard included |

| Monitor | 1 × 27-inch |

| Cables, power supply, drive, controllers | All included |

| Additional communication ports on base station for equipment | Ethernet Cat 6 RJ54, USB-A 3.0 |

| Note: Use the system in a low-vibration environment. Excessive floor or acoustical vibration can negatively impact system performance. Although the base of the station includes a passive vibration isolation system, the expected vibration level for the operation of the OPAL-MD-100 should be equal to or below the VC-A vibration criteria curve for best performances, especially for edge-coupling alignment. The velocity should be below 50 μm/s, when measured by the one-third octave bands of frequency over 8 to 80 Hz. At this level, vibrations are not perceptible. Else, contact us for more information on an active vibration damping system. a. The exact mass of the main system depends on the selected configuration. b. Use the system in a controlled environment. Environmental temperature variations will degrade performance. | |